What is ZDT Series Automatic Recirculation Pump Protective Valve

ZDT series automatic circulation pump protection valve is a pump protection device. It automatically protects the centrifugal pump (especially the hot water medium) from partial cavitation damage and instability that may occur in the pump body during low load operation. Once the pump flow rate falls below the preset rate, the bypass fully opens to ensure the minimum flow required by the pump. Even if the main route is completely closed, that is, the minimum traffic can be automatically cycled through the bypass. The pressure is reduced by an integrated multistage throttle reducing valve in the bypass. The ZDT series has a larger diameter bypass. This valve is used for large bypass flows with differential pressure up to 4MPa, the specific selection is determined by the factory.

What are the characteristics of ZDT Series automatic recirculation pump protective valves?

Simple structure, reliable and stable operation, only a few moving parts.

Easy to install, can be installed vertically or horizontally at the pump pressure outlet.

The bypass flow is large, up to 60% of the main flow, and the KV value can be adjusted.

The maximum working pressure difference of the bypass is 4MPa. Optionally, add the bypass check function.

Applicable to water, oil, methanol and other liquid media. Operating temperature from -196℃ to +300℃.

ZDT series automatic recirculation pump protective valve principle

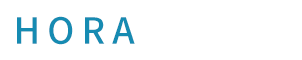

The main disc check cone of the automatic recirculation valve will automatically move to a certain position according to the sensed main flow. At the same time, the main valve disc drives the stem of the bypass valve, and transmits the action of the main valve disc to the bypass. By controlling the position of the bypass valve disc, the throttling area of the bypass is changed, and the flow through the bypass is controlled. When the main disc returns to the seat closed position, all flow is returned via bypass. When the main disc is raised to the top position, the bypass is completely closed and all pump flow flows to the process system. The valve integrates four functions in one.

Flow sensing: The main disc of the automatic recirculation valve automatically senses the main flow rate in the process system and determines the position of the main disc and bypass disc based on this flow rate.

Recirculation control: The automatic recirculation valve can draw the minimum flow required for normal operation of the pump into the storage device through bypass, adjust the H-Q characteristics of the pump, and achieve recirculation.

Bypass multistage decompression: The bypass control system can reduce the reflux medium from the high pressure at the pump outlet to the low pressure suitable for the reflux storage device with low noise and low wear.

Check: The automatic recirculation valve also acts as a check valve to prevent the liquid from flowing back into the pump body. ZDT bypass check is optional.

Other bypass sizes can be made according to requirements; The maximum bypass flow depends on the maximum Kv value

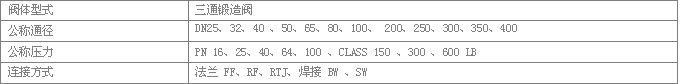

ZDL series automatic recirculation valve size pressure range